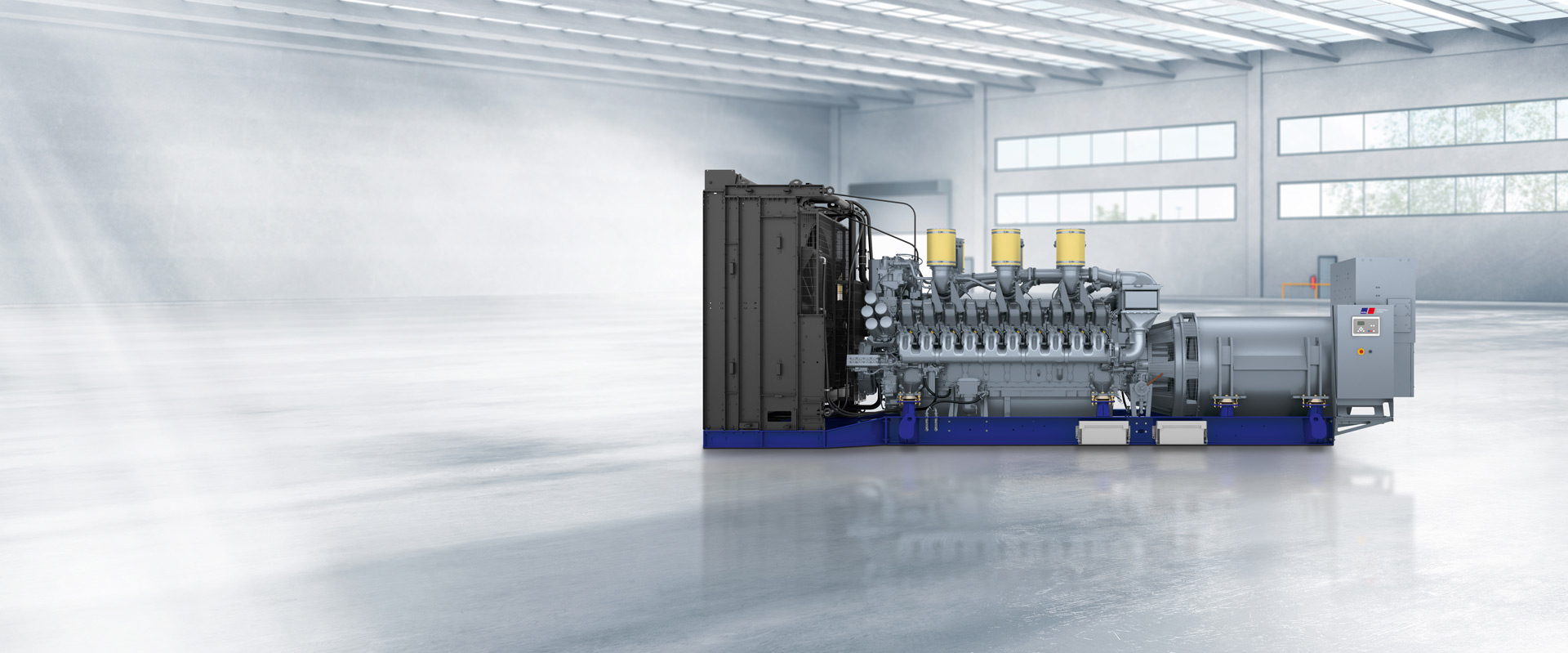

Top level performance, robust design and optimal fuel consumption. With six different ratings for flexible decentralized energy.

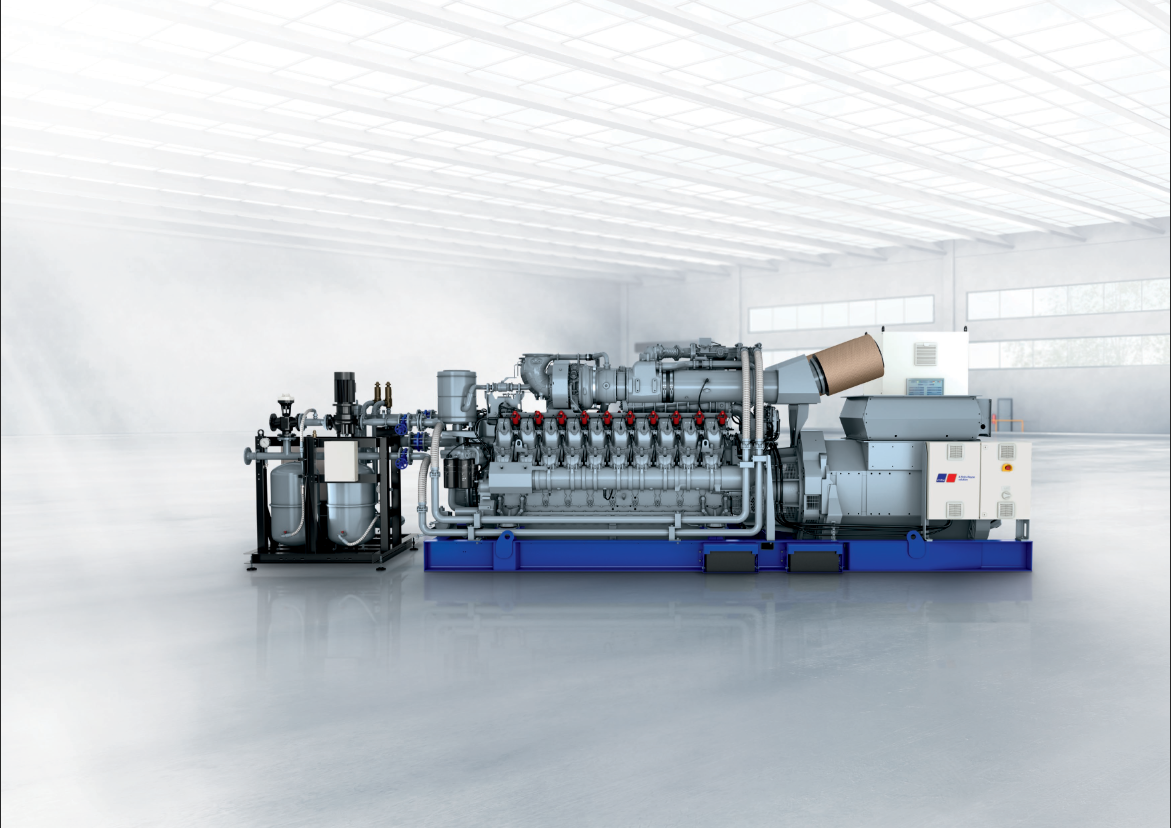

Backed by decades of experience and complete system expertise, we provide reliable gas gensets for a wide variety of applications.

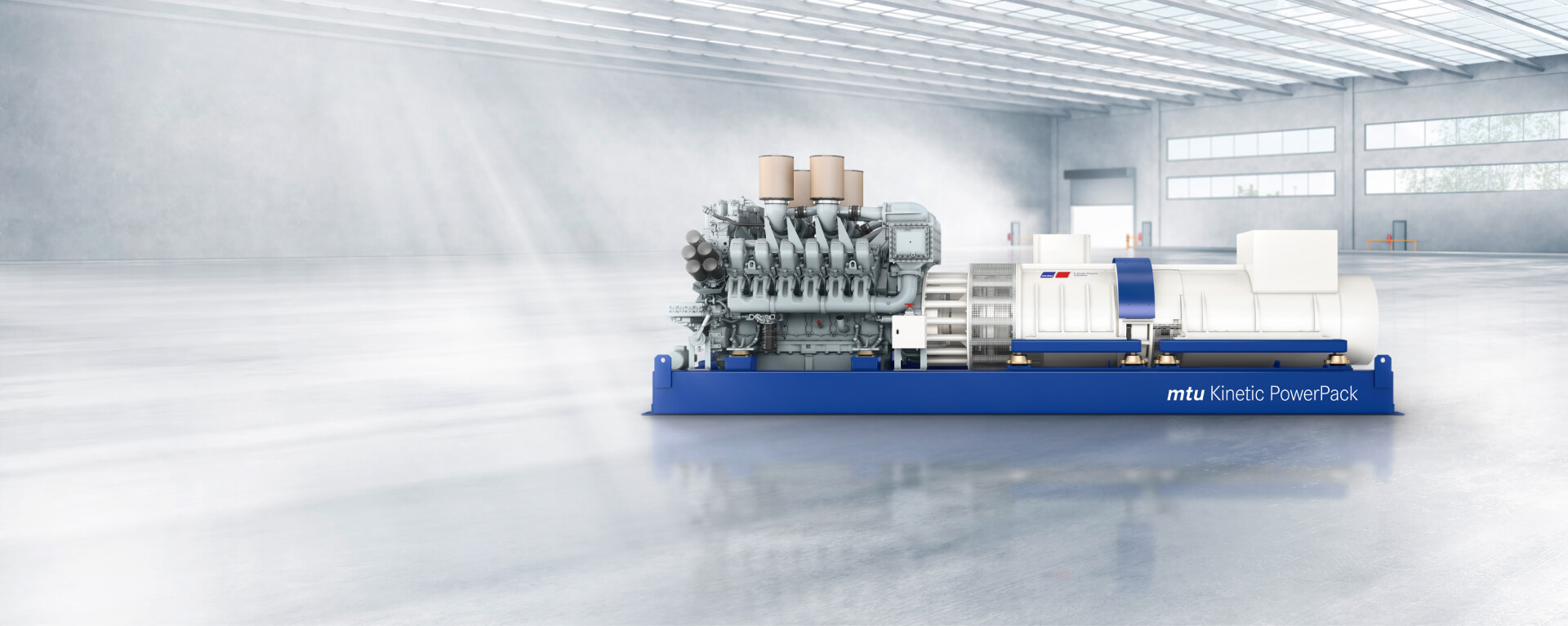

Answering your specific power, footprint, and sustaina bility needs, mtu Kinetic PowerPacks provide a competitive alternative compared to static UPS systems.

Whenever pure speed is needed, MTU propulsion systems provide incredible power and maneuverability paired with an impressive level of durability

mtu engines achieve a high-power output due to their excellent torque behavior, while they also offer outstanding efficiency through maximum uptime.

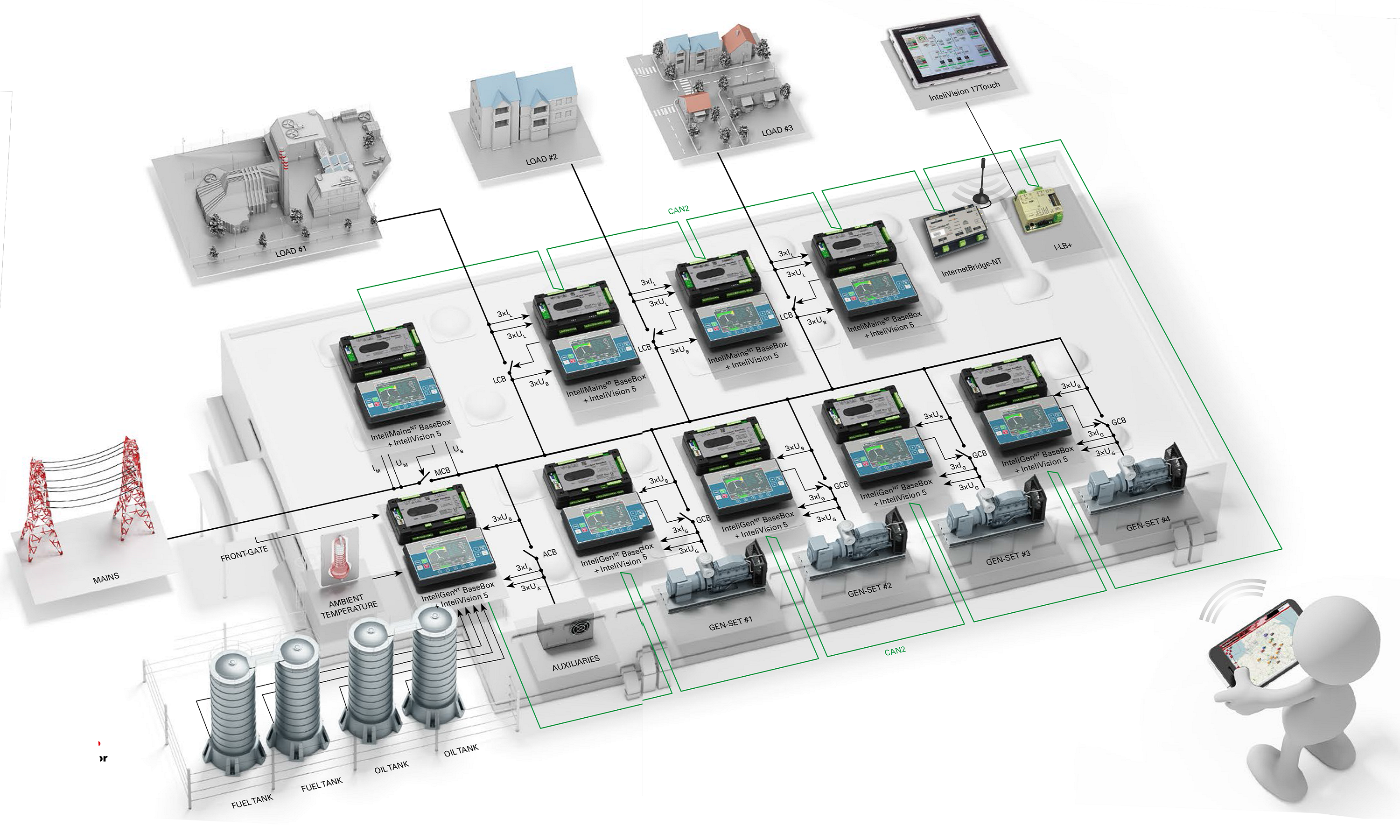

Synchronizing Panel Low Voltage Medium Voltage & Controllers Applications

TAKING PARTNERSHIP TO NEW LEVELS: COMPLETE POWER SYSTEM SOLUTIONS

mtu is one of the world’s leading manufacturers of large diesel engines and complete propulsion systems. Together with mtu A Rolls-Royce solution, mtu is one of the leading brands of Rolls-Royce Power Systems. Its product range is the widest and most modern in the sector. It covers diesel engines as well as complete propulsion systems for Generator Sets System, ships, for heavy agricultural, rail and military vehicles, and for the oil and gas industry. During a history spanning more than 100 years, the Rolls-Royce Power Systems subsidiary mtu Friedrichshafen and its predecessors, including Maybach-Motorenbau GmbH in particular, have been responsible for repeated innovation and have continually been at the forefront of technological progress.

With common rail fuel injection, the combustion process can be optimized to achieve low pollutant levels combined with lower fuel consumption. Fuel is injected into the combustion chamber from a common rail under high pressure. The electronic control system ensures that the start of injection, the quantity and time are independent of the engine speed. In 1996, with the Series 4000 engine, mtu was the first manufacturer of large diesel engines to introduce common rail fuel injection as a standard feature.

The brain of a modern engine is the electronic control unit. It monitors and controls all the key functions of the engine and the exhaust aftertreatment system. The control unit also acts as the interface to the vehicle’s automation system. The optimum interplay of the entire drive system is the key to low pollutant emissions, low fuel consumption and high power output over the entire service life. mtu develops and manufactures this key technology in-house.

The performance of an internal combustion engine can be increased by adding turbocharging. A turbocharger compresses the air so that more oxygen flows into the combustion chamber. In this way, more fuel is burned and the power output of the engine increases accordingly. The turbocharger is driven by exhaust gas, which makes turbocharged diesel engines very efficient. mtu develops this key technology for high-performance engines in-house.

Nitrogen oxide (NOX) emissions can be reduced using internal engine technology by cooling some of the exhaust gas, which is then redirected back into the charge air. This results in the reduction of the combustion temperature and less nitrogen oxide is produced. This process is known as exhaust gas recirculation (EGR) and is one of the principal methods used to reduce nitrogen oxide emissions from diesel engines. mtu has been testing this key technology for years. As a standard feature, it will be included for the first time in Series 4000 engines — starting mid-2011 in oil & gas engines for hydro frac applications to ensure compliance with EPA Tier 4 interim emission standards, followed by rail applications who need to meet EU Stage IIIB emission standards which come into force in 2012

Designing a generator set for proper vibration isolation has far-reaching consequences. Vibration induced into the building surrounding a power system can adversely affect sensitive equipment and cause tactile sensations in humans that contribute to fatigue. Vibration may also become a noise source or induce other structures to emit noise. Plus, vibration is a significant contributor to a generator set’s dynamic loading on its supports, which, in turn, affects the generator/base combination’s interface with the rest of the structure. Minimizing generator set vibration can both reduce the transfer of energy to building structures—that is, the dynamic loading of the building by the generator set—and lead to longer life for generator set components.

With the expanding use of diesel generator sets for emergency standby power, peak shaving and demand response, there has come an increased focus on controlling the noise these generators create. Whether generator sets are located in enclosures outside a facility, inside or on the roof, design engineers are making more efforts to control generator set noise and vibration in order to reduce the effects on neighbors and building occupants alike. And whether generator sets run continuously in prime-power applications, intermittently in demand response applications, or occasionally in emergency standby situations or testing, their operating sound levels may require remediation.

Achievements

Rolls-Royce Power Systems with the Plants 1 and 2 in Friedrichshafen recently received the GEO Award.

By Rolls-Royce Power Systems AG

More Info

Power Generation

Rolls-Royce is using mtu EnergetIQ to control its smart energy systems – all the way from simple emergency generator sets to complex microgrid set-ups. EnergetIQ is flexible, scalable and based on Artificial Intelligence.

By mtu Solutions

More Info

Power Generation

Are we on the way to climate-neutral data centers? Experts from Rolls-Royce Power Systems provide an outlook.

By mtu Solution

More Info

Marine Engines

Heading for the future with e-methanol: Rolls-Royce develops high-speed mtu methanol engines as a game-changer for climate-friendly shipping.

By mtu Solution

More Info

Providing you with the latest news, technical support, turnkey solution

02 Ngo Duc Ke Street, Ben Nghe ward, District 1, Ho Chi Minh City - Viet Nam

Tel: +84 28 62581136 (7 lines)

Fax: +84 28 62581137

L2-R2-13 Royal City, 72A Nguyen Trai Street, Thanh Xuan District, Ha Noi City - Viet Nam

Tel: +84 24 6262 0962 (3 lines)

Fax: +84 24 62620963

401-3 Binh Loi Street, ward 13, Binh Thanh District, Ho Chi Minh City - Viet Nam

Tel: +84 28 62581136 (7 lines)

Fax: +84 28 62581137